Climate Change

Sharp’s Stance on Climate Change

Achieving a Net-Zero Economy

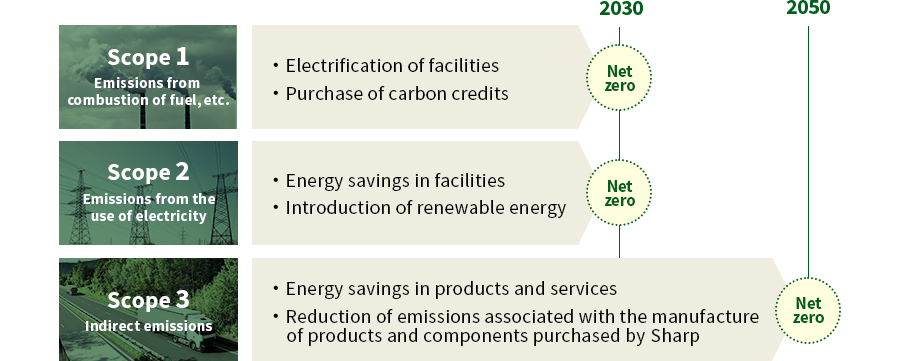

As climate change risks become more apparent and severe worldwide, society is demanding that companies take further action toward transitioning to a net-zero society. In response, Sharp is aiming to achieve net zero CO2 emissions from its own business activities (Scopes 1 and 2) by 2030, and net zero indirect CO2 emissions outside the scope of its activities (Scope 3) by 2050. For Scope 1, Sharp will electrify its facilities and purchase carbon credits. For Scope 2, it will save energy in facilities and introduce renewable energy. For Scope 3, Sharp will make its products and services more energy efficient as well as strengthen cooperation with suppliers to reduce CO2 emissions associated with the manufacture of products and components purchased by Sharp.

Achieve Net Zero CO2 Emissions across the Entire Supply Chain by 2050

Climate Change Initiatives Based on the Medium-Term Management Plan

In May 2025, Sharp announced its medium-term management plan through fiscal 2027 aimed at accelerating its future growth. In order to accelerate the global expansion of its brand business, as well as the transformation of its business, Sharp has reorganized its brand business into two business groups. One is the Smart Life Business Group, which is centered on daily living, and the other is the Smart Workplace Business Group, which is centered on working. In each of these areas, Sharp will focus and transform its business and work to create new value.

In response to climate change, Sharp will introduce generative-AI compatible products in its brand business and launch unique AI services that utilize data, thereby expanding Sharp’s AIoT business in terms of both products and services. It will continue to pursue value creation that is tailored to each individual, while optimizing energy usage to achieve further power and energy savings. In its display device business, Sharp will work to expand the supply of products, such as ultra-low-power-consumption, in-vehicle displays (for EVs) that use Sharp’s distinctive IGZO technology and the ePoster electronic paper display that consumes 0W of power when displaying images. Furthermore, Sharp will work to realize innovation in new industrial fields, such as EVs, AI data center solutions, industrial digital transformation, robotics, and outer space.

Sharp will achieve steady business expansion while responding to climate change by strengthening collaboration both inside and outside the company more than ever before, refining its core technologies, accelerating the search for future technologies, and taking on the challenge of creating innovations in a variety of fields.

Participation in Climate Change Initiatives and Other Efforts

Sharp participates in the Science Based Targets initiative (SBTi)*1, which is focused on pursuing action that will achieve real and reliable results in the fight against climate change, and in March 2024 obtained SBT 1.5℃*2 certification. Also, in order to further accelerate its plan to convert the electricity used in its business activities to 100% renewable energy, Sharp joined the RE100*3 global initiative in February 2025. It will contribute to decarbonization by actively introducing renewable energy at its business sites as well as further promoting the use of renewable energy throughout society through its energy solutions business.

In Japan, Sharp will continue to participate in the Liaison Group of Japanese Electrical and Electronics Industries for Global Warming Prevention*4 and the GX League*5 to promote initiatives by the electrical and electronics industry, along with collaborative efforts across industry, government, and academia and contribute to efforts aimed at achieving carbon neutrality for society as a whole.

Reducing Greenhouse Gas Emissions across the Supply Chain

For greenhouse gas emissions across the entire Sharp value chain, emissions from its own activities (Scopes 1 and 2) account for 3.5%, and indirect emissions outside the scope of its activities, such as emissions associated with material procurement, transportation, and the use of sold products (Scope 3), account for 96.5%. Because of this, Sharp recognizes the importance of reducing greenhouse gas emissions across its entire supply chain, not only through its own efforts to reduce the environmental impact of its activities, like product manufacturing, but, also, through efforts to reduce the environmental impact of material procurement and product use by customers (improving product energy efficiency).

Greenhouse gas emissions from Sharp’s activities are expected to decrease gradually as it makes progress with the asset-light initiative implemented in fiscal 2024. However, to ensure it achieves net zero emissions in 2030, Sharp will continue to pursue various reduction measures and the introduction of renewable energy. As part of its reduction efforts, Sharp is conserving energy at its production sites (such as by switching to LED lighting and improving the efficiency of outdoor air-processing units and air-conditioning systems). Sharp is also moving forward with the use of renewable energy, such as by introducing solar power systems at its production sites both in Japan and overseas. The utilization rate of renewable energy in its electricity consumption reached 25% by fiscal 2024.

In materials procurement, Sharp will further strengthen cooperation with its business partners to reduce greenhouse gas emissions. In the field of transportation, Sharp continues to pursue a modal shift (a switch from truck-based transportation to environmentally friendly methods like ships and railroads) while also working to optimize landing points and review its parts procurement sources.

Sharp is actively working to create environmentally friendly products and devices whose use will result in reduced greenhouse gas emissions, as these emissions account for the largest portion across the company’s entire supply chain. Sharp designates its environmentally friendly products and devices as “Green Products” and “Green Devices.” It has formulated and implemented guidelines that summarize the development and design rules of these products and devices in order to ensure it is continually working to improve their environmental friendliness.

Contributing to Society through the Widespread Adoption of Renewable Energy

“As a manufacturer of products that consume electricity, we have a responsibility to become a manufacturer of electricity itself.” This has been the motivating resolve behind Sharp’s work on solar power generation begun in 1959. Sharp’s efforts over the last half century have expanded into a wide range of fields, from residential use to power generation under harsh conditions in lighthouses and satellites, to mega solar power plants around the world. Based on its medium-term management plan, Sharp will also work to develop and deepen its core technologies in the energy sector, such as solar cells for space-based applications and perovskite solar cells.

Sharp will continue to work to further promote the use of renewable energy in all sectors of society and to contribute to the realization of a net-zero economy.

- This climate change-related initiative is a collaborative effort of the United Nations Global Compact (UNGC), the CDP, World Resources Institute (WRI), and the World Wide Fund for Nature (WWF). The SBTi promotes the establishment of science-based GHG emissions reduction targets in conformance with the Paris Agreement.

- A target of limiting the increase in global average temperatures to 1.5°C above pre-industrial levels.

- A global initiative that aims for companies to cover 100% of the electricity used in their operations with renewable energy.

- This group comprises companies from electrical and electronics industry associations in Japan, such as the Japan Electrical Manufacturers’ Association (JEMA) and the Japan Electronics and Information Technology Industries Association (JEITA). The Liaison Group undertakes industry-wide efforts aimed at preventing global warming—for example, proposing action plans to achieve carbon neutrality.

- GX stands for ‘green transformation’—an initiative to transform society into being carbon neutral by 2050. The GX League is a forum where companies pursuing sustainable growth collaborate with other companies, government, and academic organizations that share the same GX goals.

Avoided Emissions

Calculating Avoided Emissions

In addition to reducing greenhouse gas (GHG) emissions throughout its supply chain, Sharp will contribute to reducing those emissions throughout society by switching to innovative products with improved energy efficiency. This initiative is calculated as “avoided emissions*1.”

Avoided emissions are the amount of GHG emissions reduced in society as a result of the use of a company’s energy-saving products and services. They are a new indicator for evaluating a company’s ability to address problems as a solutions provider that offers solutions to the social issue of climate change. Sharp’s avoided emissions in fiscal 2024 were 122,000 t-CO2.

Avoided Emissions Calculation Method

With reference to various guidelines and case studies on avoided emissions*2, Sharp utilizes the following approach to calculating avoided emissions. This calculation method will be revised as appropriate if any new standards are established or guidelines are updated regarding the concept and calculation methodology of avoided emissions.

Avoided Emissions (Fiscal 2024)

| Avoided emissions type | Products subject to calculation | Avoided emissions (thousand tons CO2) |

|---|---|---|

| Replacement with energy-saving products | TVs, air conditioners, refrigerators, washing machines, microwave ovens, laundry dryers/dehumidifiers | 122 |

Calculation target: Six major products of Sharp brand business

TVs, air conditioners, refrigerators, washing machines, microwave ovens, laundry dryers/dehumidifiers.

Calculation scope: CO2 emissions associated with electricity consumption during product use

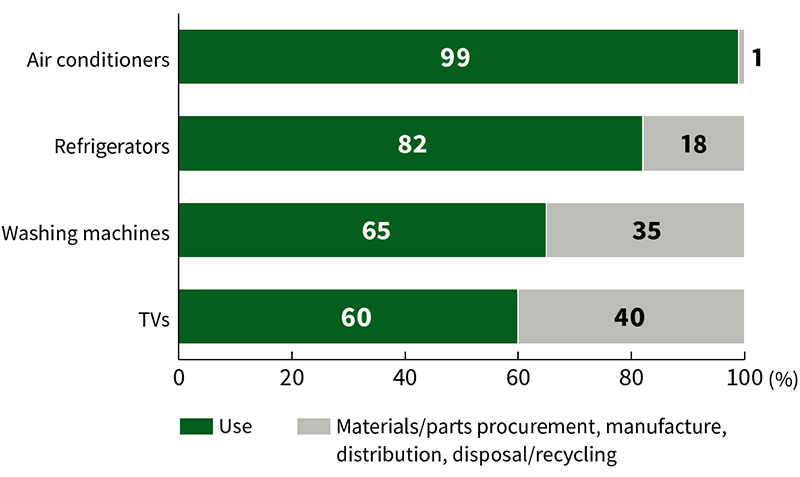

Because the “use” stage accounts for approximately 90% of the CO2 emissions in the life cycle of Sharp products, Sharp has determined that other stages such as “procurement” and “manufacture” can be excluded.

Baseline: Comparison with the average product on the market in the calculation year*3

The CO2 equivalent of the electricity consumed by an average product with equivalent functionality to Sharp’s products in the market in the country or region where it is sold in the fiscal year of calculation.

Calculation period: Flow method

The lifetime is set taking into consideration the period during which repair parts for Sharp products are available and the results of investigations into the period during which the products are used.

Calculation formula: Calculated using the following formula

(Annual power consumption of average products on the market – Annual power consumption of Sharp products*4) × CO2 emissions factor associated with electricity usage*5 × Annual sales volume of Sharp products × Lifetime

- Avoided emissions have a different purpose and calculation method from the emissions from a company’s own activities (Scopes 1 and 2) and indirect emissions outside the scope of a company’s activities (Scope 3) and does not offset these.

- Guidance on Avoided Emissions (WBCSD, March 2023), Guidelines for Quantifying Avoided Greenhouse Gas Emissions (Ministry of Economy, Trade and Industry, March 2018), Avoided Emissions: Hypothetical Cases for Avoided Emissions Disclosure (GX League, May 2024).

- Based on regulations and survey results (including Sharp’s own findings) in the country and region where the product is sold.

- Sharp uses regulations and survey results from the country and region in which each product is sold (including Sharp’s own findings and calculations).

- Uses the total CO2 emissions factor associated with electricity consumption in the country or region where the product is sold (IEA Emissions Factor 2024).

Front-Loading Washer/Dryer Achieves Industry’s Highest Level of Energy Efficiency

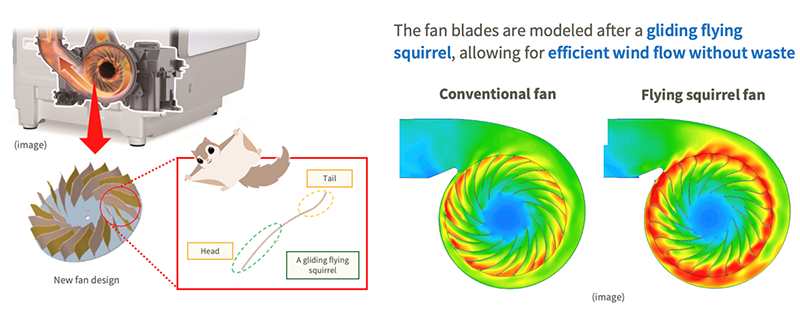

Nature technology—flying squirrel fan

In addition to a hybrid drying technology that combines a heat pump and support heater, this product is also equipped with a new type of drying fan that uses Sharp’s unique biomimetics. By increasing the amount of air sent into the tub and improving drying efficiency, Sharp has reduced the amount of power consumed for each wash and dry cycle, achieving the industry’s highest level of energy efficiency.

Inverter Air Conditioners for the Indonesian Market

J-Tech-Inverter technology

In the Indonesian market, Sharp is working to spread the use of inverter air conditioners. Demand for air conditioners in Indonesia is increasing year by year, and air conditioners are used for long periods throughout the year. Sharp believes that by popularizing inverter air conditioners, it can contribute to reducing CO2 emissions throughout Indonesian society. Sharp’s air conditioners are equipped with J-Tech-Inverter technology (compressor and motor control technology), which effectively controls power consumption compared to conventional fixed-speed air conditioners, achieving energy savings and highly energy-efficient operation.

Energy-Saving Refrigerator Operation Using AI and Wireless LAN

Energy-Saver 25 technology and Connect to Save More* cloud service function

Sharp refrigerators utilize Energy-Saver 25 technology (sensors, various controls, etc.) to achieve energy savings of up to 25% compared to normal operation.

The refrigerator’s Connect to Save More cloud service function connects to a wireless LAN and enables AI on the cloud to learn about how the refrigerator is used and then to operate in an energy-saving manner according to the user’s lifestyle. By combining this with Energy-Saver 25, it is expected that energy savings of up to 35% can be achieved compared to normal operation.

- Although Connect to Save More was not reflected in this calculation, it is expected that the utilization of this technology will reduce the amount of power consumed during product use, leading to further reductions in CO2 emissions.

Future Avoided Emissions Initiatives

Currently, Sharp calculates avoided emissions for the six main products of its brand business. In the future, it will consider methods for calculating avoided emissions for other products, services, and solutions. Furthermore, by setting medium- to long-term targets, Sharp will accelerate its technological innovation and use its distinctive technologies to contribute to decarbonization not only in Japan but also in Asia and around the world.

TCFD-Based Information Disclosure

Action on the TCFD Recommendations

The Task Force on Climate-related Financial Disclosures (TCFD) was established by the Financial Stability Board (FSB), an organization promoting international financial stability. In 2017 the TCFD released recommendations for companies to disclose information on the risks and opportunities of climate change. Sharp has declared support for the TCFD recommendations and is expanding disclosure of climate-related information in accordance with the framework set by the TCFD.

1. Governance

Climate-related issues are monitored and countermeasures supervised by the president & CEO, who chairs the Sustainability Committee. The committee includes senior executives and members from head office departments, business units, and subsidiaries. The committee works to thoroughly implement policies and visions related to aspects of ESG such as climate change; it deliberates on and promotes active measures; and it shares the latest trends on societal issues.

Through monitoring and review by management at committee meetings, Sharp continuously strengthens climate change action to play a part in making society sustainable.

2. Strategy

Sharp sees climate change as both a risk and an opportunity in the medium to long term. We are studying strategies and learning about organizational resilience in the context of climate change-related risks and opportunities. To understand long-term impacts up to 2050, we analyzed climate change scenarios outlined by the International Energy Agency (IEA) and the Intergovernmental Panel on Climate Change (IPCC) (1.5°C scenario*1 and 4°C scenario*2). The following page provides detailed information about those risks and opportunities, along with a summary of associated measures.

3. Risk Management

Sharp identifies and assesses climate-related risks in accordance with the Rules of Business Risk Management, in which the basic approach to risk management has been established. Specifically, Sharp identifies climate-related risks that are highly likely to occur based on its analysis of climate scenarios forecast for the future. Sharp reports its findings as necessary to senior executives and the Internal Control Planning Division, which serves as the risk management secretariat. It also facilitates necessary improvement measures in partnership with involved departments.

4. Metrics and Targets

In 2019 Sharp formulated SHARP Eco Vision 2050, a long-term environmental vision based on its basic environmental policy of “Creating an environmentally conscious company with sincerity and creativity,” which was established in 1992. Sharp is working toward realizing a sustainable global environment by pursuing long-term goals set in three fields of action with 2050 as the target year: climate change, resource recycling, and safety and security. With regard to the pressing global issue of climate change, Sharp is accelerating efforts to achieve net zero CO2 emissions from its business activities (Scopes 1 and 2) by 2030, and from its entire supply chain (Scopes 1, 2, and 3) by 2050.

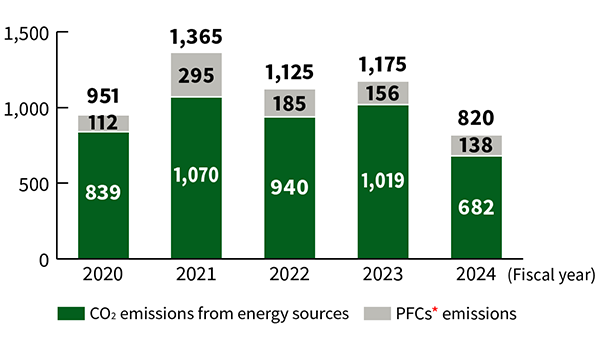

Progress towards Reducing GHG Emissions (Fiscal 2024 Results)

| Base Year (fiscal 2021 results) |

Fiscal 2024 Results | Base Year Comparison |

|---|---|---|

| 1,365 thousand tons CO2 | 820 thousand tons CO2 | 39.9% reduction reduction |

- IEA Net Zero Emissions by 2050 Scenario; SSP1-1.9 scenario from the IPCC 6th Assessment Report (AR6).

- RCP 8.5 scenario from the IPCC 5th Assessment Report (AR5).

Business Risks and Opportunities; Sharp’s Response

| Scenario | Factors | Changes | Impacts on Sharp | Risk or Opportunity | Degree of Impact | Time Until Impact Becomes Apparent* | Sharp’s Response |

|---|---|---|---|---|---|---|---|

| 1.5℃ | Introduction of carbon pricing | Increased raw material procurement costs | Costs passed on to purchase prices due to carbon tax levied on Sharp-purchased products | Risk | Large | Short term |

|

| Increased direct operational costs | Increased payment costs due to carbon tax levied in line with Sharp’s GHG emissions | Risk | Large | Short term |

|

||

| Pressure to decarbonize and pursue environmental friendliness in the supply chain | Decline in competitiveness due to failure to meet user needs for environmental friendliness | Decrease in sales due to failure to meet user expectations for environmental friendliness | Risk | Medium | Short term |

|

|

| Increased costs associated with switching to environmentally friendly materials | Increased costs associated with switching to electric furnace materials, recycled plastic, and bio-plastic, which emit less GHGs | Risk | Medium | Medium term |

|

||

| Increased energy procurement costs due to switching to renewable energy | Increased costs associated with in-house power generation, power purchase agreements (PPA), switching to renewable energy, and purchase of environmental value certificates | Risk | Small | Medium term |

|

||

| Expansion of the renewable energy market | Increased demand for solar power-related products and systems from producers and users of renewable energy | Increased possibility for revenue growth by expanding product and system offerings | Opportunity | Medium | Short term |

|

|

| Increased demand for zero energy houses (ZEH) | Increased possibility for revenue growth by strengthening offerings of flat-rate solar power services for homes and home energy management systems (HEMS) | Opportunity | Medium | Short term |

|

||

| Expansion of environmental protection businesses | Expansion of circular economy business models | Increased support from customers by establishing a waste-free circular economy business model, amid growing efforts for decarbonization in society | Opportunity | Small | Medium term |

|

|

| 4℃ | Intensifying weather-driven disasters | Disruptions in the supply chain | Intensifying weather-driven disasters affect Sharp suppliers and bases and the supply chain, leading to a loss in sales opportunities for Sharp | Risk | Medium | Long term |

|

- Short term: three years or less; medium term: by around 2030; long term: by around 2050.

Greenhouse Gas Emissions Based on the GHG Protocol Initiative

Sharp calculates greenhouse gas emissions based on the GHG Protocol*1 and then works to limit those emissions across the entire supply chain.*2

Greenhouse Gas Emissions by Scope 1/2/3 Categories Based on the GHG Protocol Initiative (Fiscal 2024)

| Category | Emissions (Thousand Tons CO2) |

Notes | |

|---|---|---|---|

| Scope 1 (direct GHG emissions from business activities) | 260 | Emissions from combustion of fuel, etc. | |

| Scope 2 (indirect GHG emissions from energy usage in business activities) | 560 | Emissions from the use of electricity. Location-based emissions (calculated using the average emission intensity of each region) were 765 thousand tons CO2 | |

| Total of Scope 1 and Scope 2 | 820 | ||

| Scope 3 (indirect GHG emissions from outside the scope of business activities) |

1.Purchased goods and services | 1,879 | Emissions from the manufacture of materials procures for products sold in the reporting year |

| 2.Capital goods | 82 | Emissions from the construction, manufacture, and transportation of capital goods (such as equipment, machinery buildings, facilities, and vehicles) | |

| 3.Fuel-and energy-related activities (not included in Scope 1 or 2) |

150 | Emissions from the procurement of fuels (natural resource extraction, manufacture, and transportation ) consumed in the generation of electricity and heat procured from other companies | |

| 4.Upstream transportation and distribution | 153 | Emissions from the transportation of parts and materials and products manufactured | |

| 5.Waste generated in operations | 2 | Emissions from waste disposal and treatment | |

| 6.Business travel | 16 | Emissions from business travel by all employees | |

| 7.Employee commuting | 15 | Emissions from commuting by all employees | |

| 8.Upstream leased assets | - | Included in Scope 1 and 2 emissions | |

| 9.Downstream transportation and distribution | 63 | Emissions from the transportation (from retailers to end consumers) of main products*3 sold in the reporting year | |

| 10.Processing of sold products | 44 | Emissions from processing at destination of products | |

| 11.Use of sold products | 19,337 | Emissions*4 from the use of the main products*3 sold in the reporting year | |

| 12.End-of-life treatment of sold products | 809 | Emissions from recycling 4 types of appliances*5, copiers/MFPs, and PCs. And emissions of refrigerants when disposing of air conditioners | |

| 13.Downstream lease assets | - | Not applicable | |

| 14.Franchises | - | Not applicable | |

| 15.Investments | - | Not applicable | |

| Scope 3 total | 22,533 | ||

| Scope 1 + 2 +3 total | 23,353 | ||

- The GHG Protocol is an international standard for calculating greenhouse gas (GHG) emissions. It was jointly established by the World Business Council for Sustainable Development (WBCSD), a coalition of the world’s leading companies, and the World Resources Institute (WRI), a United States-based think tank.

- Scopes 1 and 2 are calculated for Sharp Corporation production sites and production subsidiaries in Japan and overseas. Scope 3 is calculated for Sharp’s entire supply chain.

- Flat-panel TVs, air conditioners, refrigerators/freezers, washing machines/dryers, air purifiers, Plasmacluster Ion generators, microwave ovens, copiers/MFPs, solar cells.

- Annual power consumption of each product × number of units sold × product life × CO2 emission coefficient.

- TVs (CRT TVs, flat-panel TVs), air conditioners, refrigerators/freezers, washing machines/dryers.

Reducing Business Activity-Linked Greenhouse Gas Emissions

| Fiscal 2024 Objectives | Fiscal 2024 Achievements | Self-Evaluation | Priority Objectives for Fiscal 2025 |

|---|---|---|---|

|

|

★★★ |

|

- Self-evaluation: ★★★ Achieved more than targeted / ★★ Achieved as targeted / ★ Achieved to some extent

To address the global problem of climate change, Sharp is working to reduce GHG emissions from its business activities. We aim to achieve net zero CO2 emissions from business activities by 2030. The Sharp Group’s GHG emissions from business activities in fiscal 2024 was down 39.9% to 820,000 tons CO2 compared to the previous fiscal year.

In addition to energy-saving actions at each site, Sharp is using non-fossil certificates to reduce the amount of greenhouse gas emissions. As well, as part of structural reform aimed at achieving a brand-business-focused portfolio, efforts such as selling assets in the device business, where energy consumption is high, and optimization of manufacturing capacity allowed us to dramatically reduce emissions.

We will continue to achieve targets by, for example, making production lines more efficient and introducing renewable energy.

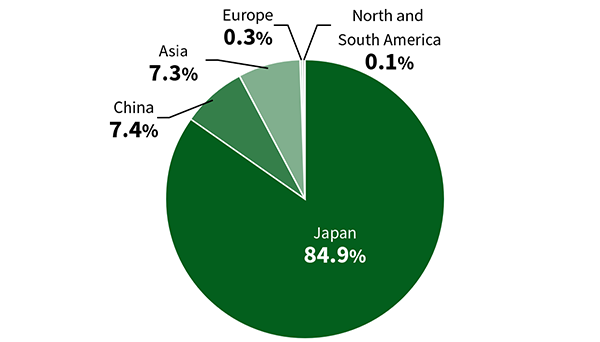

Sharp Group’s GHG Emissions from Business Activities

GHG Emissions by Region (Fiscal 2024)

- HFCs, PFCs, sulfur hexafluoride (SF6), nitrogen trifluoride (NF3).

Reducing Greenhouse Gas Emissions at Production Sites

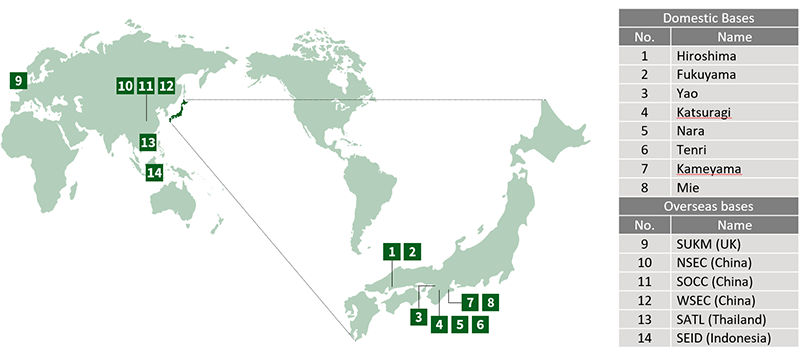

WSEC, Sharp’s production base in China, has upgraded the electronic control system for the factory’s air conditioning equipment and implemented total optimization control. It also takes other energy-saving measures, like replacing factory lights with LED lamps. In addition, a solar power system with an output of 2 MW-dc and annual power generation of 2,485 MWh was installed on the factory roof. As a result of these efforts, greenhouse gas emissions were reduced by approximately 4,000 t-CO2 in fiscal 2024.

Sharp is actively pursuing energy-saving initiatives and the introduction of solar power systems at its domestic and overseas bases as it works to reduce greenhouse gas emissions globally.

Product Life Cycle Assessment

Identifying and Reducing Environmental Impacts throughout the Life of Products

Sharp performs a life cycle* assessment (LCA) on its products to identify their impact on the environment throughout their life cycle the results in product planning and development.

Consumer electronics generally have a large impact on the environment during use. Thus, by focusing on improving their energy savings, overall environmental impact can be effectively reduced.

- The life of a product from materials and parts procurement to manufacture, distribution, use, disposal, and recycling.

Life Cycle CO2 Emissions by Percentage of the 4 Types of Appliances

Utilizing Renewable Energy

Sharp has introduced the use of PV systems and other power sources to its domestic and overseas production bases and is advancing the use of renewables to do its part to create a net-zero society. In fiscal 2024, the amount of renewable energy was 367.13 million kWh. The proportion of renewable energy in Sharp’s electricity consumption increased to 25%. In-house solar power generation was 6.99 million kWh.

Solar Power Systems at Sharp Bases Worldwide

“Life Eee Connect” Service Wins the Director-General of the Agency for Natural Resources and Energy Award at the New Energy Award 2024

Sharp’s energy management service “Life Eee Connect,” which integrates solar power systems with home appliances and residential equipment to reduce electricity costs, has won the Director-General of the Agency for Natural Resources and Energy Award in the product and service category at the New Energy Award 2024, organized by the New Energy Foundation (sponsored by the Ministry of Economy, Trade and Industry). The New Energy Award is a system that recognizes excellent examples of the development of equipment and services related to new energy and the use of distributed energy, with the aim of promoting the introduction of new energy such as solar power.

“Life Eee Connect” is an energy management service that intelligently controls home appliances and residential equipment on behalf of customers using Sharp’s proprietary AI in households with installed solar power systems. This service, which applies AI control developed through battery control, was launched in November 2023 as the industry’s first service to reduce electricity purchases by integrating control of solar power systems with home appliances and residential equipment. So far, it has achieved integration with air conditioners, water heaters, refrigerators, and front-loading washer/dryers.

The service was recognized for its effective use of surplus electricity through AI control of home appliances and residential equipment, achieving efficient electricity cost reduction, and for utilizing the common communication standard for IoT devices, “ECHONET Lite,” making it applicable to appliances and residential equipment from other manufacturers. These factors led to this award.

Sharp will continue to expand services utilizing solar power systems and battery systems, contributing to the achievement of carbon neutrality for society as a whole.

Reducing Logistics-Related Environmental Impact

Reducing the Environmental Impact of Logistics in Japan

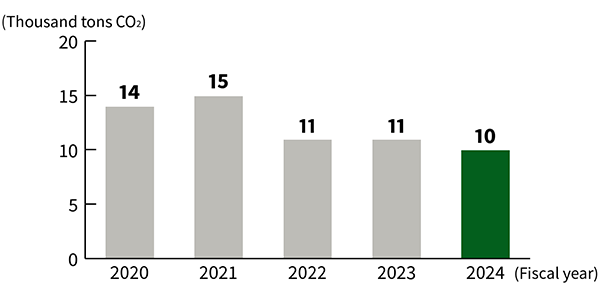

Sharp observes a rule set forth in the Japanese Energy Conservation Act*1 that requires specified shippers to reduce energy intensity by 1% or greater per year. All Sharp Group companies in Japan are working to reduce the environmental impact and costs associated with logistics.

In fiscal 2024, Sharp Group greenhouse gas (GHG) emissions from shipping activities in Japan were 10,000 tons CO2. For Sharp Corporation, energy intensity was improved by an average of 8% for the most recent five years (fiscal 2020 to 2024). Sharp is steadily implementing a modal shift*2, a change from conventional trucking to more environmentally friendly modes of transport, such as shipping (non-international coastal trading vessels) and rail (Japan Railways containers). And, by unloading imported goods at harbors chosen for their proximity to their main sales locations, Sharp is reducing re-transport between distribution centers. These efforts enable Sharp to reduce the environmental impact of its distribution activities. For shipments, Sharp has been certified with an Eco Rail Mark*3 by the Ministry of Land, Infrastructure, Transport, and Tourism and the Railway Freight Association.

- Act on Rationalization of Energy Use and Shift to Non-Fossil Energy

- To shift freight transport from conventional trucking to more environmentally friendly modes of transport, such as rail and shipping.

- Products or companies that use a certain amount of rail transport for freight are given Eco Rail Mark certification. The mark is used on items such as product packaging and brochures to inform the public that a company uses environmentally friendly modes of transport.

GHG Emissions from Freight Shipments (Japan)

Reducing the Environmental Impact of International Logistics

Sharp has a wide range of initiatives to reduce the amount of GHGs that are emitted as a result of international shipping. The company is reducing airfreight volume as it switches to environmentally friendly modes of transport, and it is also improving load efficiency. Further, it is reviewing shipping routes and switching to harbors that are closer to the final destinations for products. Sharp is also switching to suppliers located closer to its factories.