Promoting Supply Chain CSR

Determining Procurement from the Standpoint of Providing Equal Opportunity and Fair Evaluation

Sharp’s business philosophy states, “Our future prosperity is directly linked to the prosperity of our customers, dealers and shareholders.” In line with this, Sharp works with suppliers and all other stakeholders to provide solutions to social issues through business and to mitigate impacts on society and the environment as it pursues sustainable growth and mutual prosperity.

To these ends, Sharp emphasizes impartiality and fairness in all purchasing activities and chooses who it will procure parts, materials, and equipment from by providing Japanese and overseas suppliers with an equal opportunity to do business with Sharp. This opportunity includes a fair evaluation of whether a supplier meets Sharp’s requirements in such areas as quality, standards, and performance.

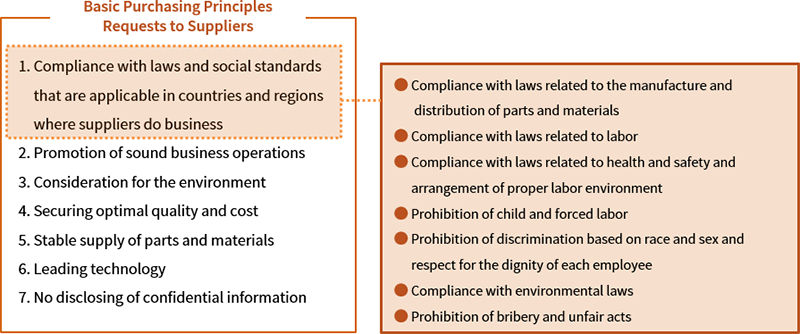

Basic Purchasing Principles

To ensure sustainable growth and mutual prosperity with its suppliers, Sharp is going beyond initiatives related to the quality, price, and delivery of parts and materials. Sharp is also seeking to fulfill its social responsibilities over a wide range of areas across the entire supply chain. These areas include product safety, environmental protection, human rights and labor, and health and safety.

Sharp’s basic concept, concrete policies, and requests to suppliers pertaining to procurement activities are set out in the Basic Purchasing Principles. In its Basic Purchasing Principles Requests to Suppliers, Sharp makes clear that it expects suppliers to actively work to ensure that, in addition to complying with all relevant laws, they also protect the environment and are in compliance with social norms, such as those regarding the arrangement of a proper labor environment, the prohibition of child and forced labor, the prohibition of discrimination, and the prohibition of bribery and unfair acts.

To deepen the understanding between Sharp and its business partners about sustainable procurement, Sharp communicates actively with supplier sales representatives on a daily basis.

Basic Procurement Concept

- Sharp's procurement activities are conducted in an open and impartial manner, with a fair evaluation given to suppliers in and outside Japan.

- Sharp will comply with all laws and regulations, and achieve mutual prosperity with suppliers.

- Sharp will fulfill social responsibility such as the conservation of the environment through its procurement activities.

- Sharp pursues optimal quality and cost to the fullest.

Overview of the Global Supply Chain

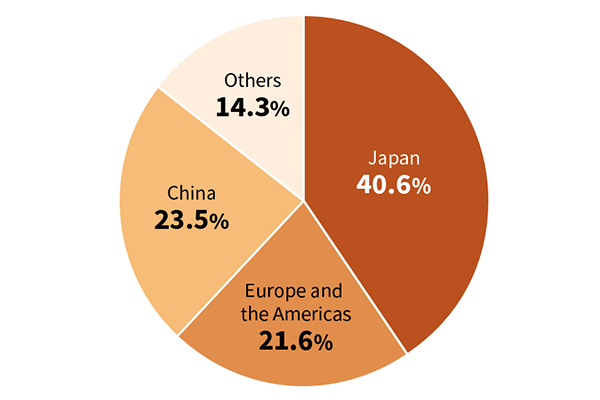

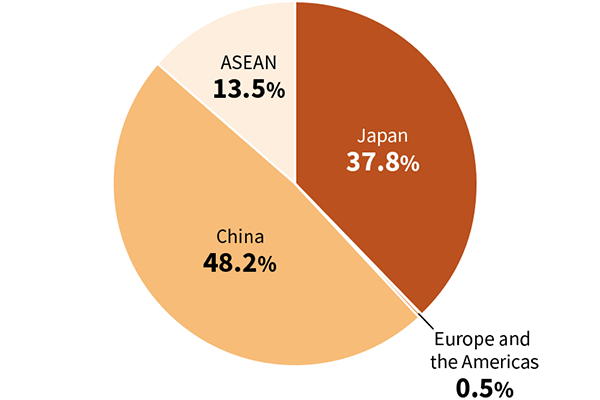

Sharp has 21 consolidated subsidiaries in Japan and 97 overseas (as of March 31, 2025). In line with the globalization of its business, 59.4% of sales are from overseas business; similarly, 62.2% of materials procurement, in terms of monetary amount, is by overseas production bases.

Sharp has established an international procurement office (IPO) in Hong Kong and South Korea to further procurement activities such as increased procurement of materials locally and more streamlined distribution.

Through increased procurement of local parts and materials, Sharp contributes to mutual prosperity with suppliers and advancement of regional economies.

Sales by Region (Fiscal 2024)

Procurement Amount Composition Ratio by Production Base (Fiscal 2024)

Promoting CSR across the Entire Supply Chain

| Fiscal 2024 Objectives | Fiscal 2024 Achievements | Self-Evaluation | Priority Objectives for Fiscal 2025 |

|---|---|---|---|

|

|

★★ |

|

- Self-evaluation:

- ★★★ Achieved more than targeted /

- ★★ Achieved as targeted /

- ★ Achieved to some extent

Supply Chain CSR Policies and Systems

The Sharp Group’s fundamental policies with regard to CSR are established in the Sharp Group Charter of Corporate Behavior and the Sharp Code of Conduct. Every effort is made to ensure that all Sharp employees are aware of and adhere to these policies.

The Corporate Procurement Group, which promotes supply chain CSR, has been organizationally strengthened as a business unit directly under the president & CEO from June 2024. It coordinates with each business unit and subsidiary’s procurement department to pursue Group-wide implementation of sustainable procurement activities.

In addition, the Sustainability Committee, which is chaired by the CEO, has set supply chain ESG risk reduction as a key initiative. At committee meetings, members from relevant head office departments, along with business units and subsidiaries, share their policies and measures. The committee also monitors and manages progress on supply chain CSR-related measures.

Sharp Supply-Chain CSR Deployment Guidebook

To help suppliers understand and put into action CSR philosophy as stated in Sharp’s Basic Purchasing Principles, in fiscal 2007 the company formulated and distributed its own Sharp Supply-Chain CSR Deployment Guidebook in Japanese, English, and Chinese. The Basic Products Purchase Agreement also includes articles on CSR initiatives, based on the guidebook, that suppliers are requested to follow. In addition, Sharp asks its business partners’ suppliers to also support and implement the guidelines in this guidebook.

In fiscal 2015, Sharp fully revised the content of its guidebook to conform to the RBA Code of Conduct. Since then, it has revised the guidebook as needed in line with revisions to the RBA Code of Conduct. In this way, Sharp strives to comply with the increasingly sophisticated international standards for CSR.

Participation in Industry Standard Initiatives

In December 2021, Sharp joined the RBA (Responsible Business Alliance), an alliance of companies that pursue social responsibility across the global supply chain. The RBA’s vision and mission are shared throughout the entire Sharp Group in order to promote sustainable procurement.

Sharp also actively participates in the activities of groups such as the Japan Electronics and Information Technology Industries Association (JEITA), through which it contributes to the promotion of industry-wide sustainable procurement.

Content of Sharp Supply-Chain CSR Deployment Guidebook, 4th Edition (revised January 2025)

A. Labor

- Prohibition of Forced Labor

- Young Workers

- Working Hours

- Wages and Benefits

- Non-Discrimination/Non-Harassment/Humane Treatment

- Freedom of Association and Collective Bargaining

B.Health and Safety

- Occupational Health and Safety

- Emergency Preparedness

- Occupational Injury and Illness

- Industrial Hygiene

- Physically Demanding Work

- Machine Safeguarding

- Sanitation, Food, and Housing

- Health and Safety Communication

C.Environment

- Environmental Permits and Reporting

- Pollution Prevention and Resource Conservation

- Hazardous Substances

- Solid Waste

- Air Emissions

- Materials Restrictions

- Water Management

- Energy Consumption and Greenhouse Gas Emissions

D.Ethics

- Business Integrity

- No Improper Advantage

- Disclosure of Information

- Intellectual Property

- Fair Business, Advertising, and Competition

- Protection of Identity and Non-Retaliation

- Responsible Sourcing of Minerals

- Privacy

E.Management Systems

- Company Commitment

- Management Accountability and Responsibility

- Legal and Customer Requirements

- Risk Assessment and Risk Management

- Improvement Objectives

- Training

- Communication

- Workers/Stakeholders Engagement and Access To Remedy

- Audits and Assessments

- Corrective Action Process

- Documentation and Records

- Supplier Responsibility

Promoting CSR Awareness and Conducting Risk Assessment at Suppliers

There has been increasing concern around the world in recent years about issues such as slave labor and forced labor. Europe and North America have led the way in enacting, enforcing, or discussing laws promoting due diligence of human rights in the supply chain. Examples include the Uyghur Forced Labor Prevention Act and the EU Corporate Sustainability Due Diligence Directive (CSDDD). Companies today are expected to be stricter than ever in implementing CSR in the supply chain.

Sharp periodically carries out CSR/Green procurement surveys to confirm how well suppliers are carrying out CSR based on the RBA Code of Conduct-compliant Sharp Supply-Chain CSR Deployment Guidebook and to identify, assess, and reduce CSR risk in the supply chain.

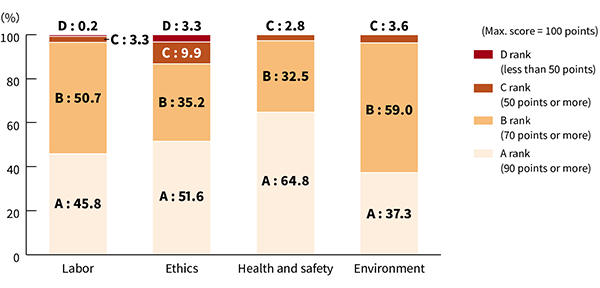

On the survey form, there are areas that conform to the RBA self-assessment questionnaire—labor, health and safety, environment, and ethics—as well as a wide range of items particular to Sharp, including biodiversity/chemical substances management, BCP (business continuity planning), and information security.

To help suppliers understand things like the purpose and background of the survey, Sharp adds its own explanations to major questions. This helps make the survey a medium that prompts suppliers to further their understanding of international CSR standards.

The survey is carried out separately at each factory of suppliers, or secondary manufacturers and downward on the supply chain, that makes products for Sharp. Survey scorecards are shared with them, and those with low-scoring areas are asked to submit corrective action plans. Through such post-survey communication with suppliers, Sharp is continuously working to improve CSR across the supply chain.

In fiscal 2024, Sharp surveyed 960 business sites of 470 companies, which account for the top 80% of Sharp’s domestic and overseas suppliers in terms of procurement value, and received responses from 713 business sites of 363 companies (a response rate of 74.2%). Of these, 35 sites received low ratings and were asked to implement corrective action plans. No serious issues, such as forced labor or child labor, were identified in the supply chain.

If, through our continuing due diligence, it was determined that a human rights violation did occur, we would immediately enter into discussions with the supplier in question based on the supplier contract, and take the necessary corrective and relief measures. If no remediation is expected, Sharp will take strict measures, such as suspending transactions, while prioritizing relief measures for victims.

Sharp will continue to step up its efforts in response to trends in international human rights due diligence as it fulfills its corporate social responsibility in every facet of the supply chain.

Assessment Distribution of CSR/Green procurement survey (All Production Sites in Japan and Overseas)

Fiscal 2024 CSR/Green procurement survey: Examples of Issues and Solutions

| Area | Supplier Issues | Supplier Improvements |

|---|---|---|

| Labor |

|

|

| Ethics |

|

|

| BCP |

|

|

| Information security |

|

|

Education for Procurement Personnel

To help all those in procurement positions company-wide improve their understanding and implementation of CSR, a thorough explanation of the Basic Purchasing Principles, along with a curriculum relating to supply chain CSR, is included in training materials for new employees, transferred employees, and management skills improvement. Additionally, all Sharp Group employees in Japan take compliance-related training based on the Sharp Code of Conduct in order to foster respect for human rights, and ESG-related training in order to gain basic knowledge about sustainable procurement. This is done to ensure that all procurement personnel within the company have undergone training on sustainable procurement.

In fiscal 2025, the plan is to implement sustainability-related learning for 100% of employees engaged in procurement work across the entire Sharp Group, including overseas bases.

Moving forward, Sharp will continue to expand and implement these educational programs in order to promote greater understanding of sustainable procurement among procurement personnel, both in Japan and overseas.

Procurement BCP

In order to enable the continuation and rapid recovery of business with its business partners in the event of large-scale disasters, such as earthquakes and typhoons, or epidemics of infectious diseases, Sharp uses the Rules of Business Risk Management to create and periodically revise business continuity plans (BCPs).

To ensure that corporate procurement departments secure a stable supply of parts and materials at fair prices, Sharp continuously strengthens partnerships with suppliers regarding long-term supply contracts and other matters, as well as purchases from multiple suppliers. Sharp also requires suppliers to periodically check and update the factories that produce items delivered to Sharp. It also carries out CSR/Green procurement surveys to confirm how well suppliers are making and maintaining BCPs.

Strengthening the Hotline and Consultation System for Suppliers

Sharp Corporation and its affiliated companies in Japan have set up the Crystal Hotline to handle organizational and individual legal and ethical violations. The hotline accepts reports and consultation requests from suppliers.

Additionally, in order to develop a grievance mechanism as required of companies by the United Nations Guiding Principles on Business and Human Rights (UNGP), Sharp became an inaugural member (regular member) of the Japan Center for Engagement and Remedy on Business and Human Rights (JaCER) in 2020.

A broad range of stakeholders, including employees of suppliers in global supply chains (including second-tier and lower suppliers) and the labor unions and NGOs that support them, have been able to make use of JaCER’s Engagement and Remedy Platform, available in 34 languages, to submit reports of human rights-related grievances.

Encouraging Business Partners to Conduct Sustainable Procurement

To help suppliers deepen their understanding of sustainable procurement, Sharp held the Sharp Supplier Summit in Japan in September 2024, where it explained its sustainable procurement policy to 261 people from 130 major supplier companies.

As a member of the CSR Committee and the Responsible Minerals Trade Working Group of the Japan Electronics and Information Technology Industries Association (JEITA), Sharp actively supports the promotion of understanding and capacity building among its suppliers, such as through its involvement in educational and awareness-raising activities on sustainable procurement, including planning and running lectures for suppliers and disseminating the latest information.

Audits and Education to Ensure Full Compliance with the Subcontract Act

In Japan, Sharp Corporation and its affiliated companies implement compliance checks and in-house education on an ongoing basis to comply with the Subcontract Act (Act Against Delay in Payment of Subcontract Proceeds, etc. to Subcontractors), a law aimed at protecting the earnings of subcontractors.

The compliance checks are self-audits conducted every year by business units, procurement departments, head office departments, and domestic affiliated companies to ensure thorough compliance with the Subcontract Act. To further raise awareness of complying with the Subcontract Act and ensure all employees related to procurement are knowledgeable in matters such as government policy on dealing with subcontractors, Sharp held in-house study sessions at each of its domestic affiliates, e-learning for approximately 12,000 employees group-wide (76.1% of all Sharp Group employees in Japan), and had employees take outside seminars.

Responsible Minerals Procurement

Policies and Systems for Responsible Minerals Procurement

In recent years, a series of laws and regulations have been enacted that obligate companies to carry out due diligence in human rights and the environment, such as the EU’s Battery Regulation and Corporate Sustainability Due Diligence Directive, in addition to the U.S. Dodd-Frank Wall Street Reform and Consumer Protection Act and the EU’s Conflict Minerals Regulation. This has meant that companies have had to take a broader range of increasingly complex efforts regarding the minerals, regions, and risks involved in the responsible procurement of minerals.

Sharp has a basic policy in place to ensure that it is not complicit in human rights abuses and environmental destruction in the supply chain for procuring minerals contained in the materials and components procured by the Group, and to take appropriate measures to avoid inhibiting sound, legitimate business activities in the local area. This involves conducting due diligence activities based on the OECD*1 Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas (OECD Guidance).

Based on this basic policy and the Sustainability Committee, which is chaired by the president & CEO of Sharp, Sharp has made responsible minerals procurement one of its key themes. A responsible minerals sourcing system has been created in major business units and production subsidiaries, and Sharp is constantly checking on the progress of relevant measures under this system.

Cooperation with Industry

To ensure that responsible minerals procurement is carried out efficiently and effectively, Sharp believes in the importance of collaborating with industries in Japan and other countries and acting based on widespread consensus. Since fiscal 2012, Sharp has been a member of the Responsible Minerals Trade Working Group of the Japan Electronics and Information Technology Industries Association (JEITA).

Furthermore, since December 2021, Sharp has been a member of the RMI*2, working to deepen our global collaboration and due diligence initiatives while ensuring we stay abreast of the latest international developments relating to responsible minerals procurement.

Minerals Procurement Due Diligence in Accordance with International Standards

Sharp uses the RMI’s international reporting templates (CMRT*3 and EMRT*4) to conduct surveys on 3TG (tantalum, tin, tungsten, and gold) and, if requested by customers, cobalt and natural mica, as well as copper, nickel, lithium, natural graphite, and other minerals, which were added to the EMRT in April 2025.

In the surveys, primary suppliers are urged to procure minerals from RMAP*5-conformant smelters or refiners. And, based on examination of the CMRT and EMRT returned by survey participants, Sharp identifies and evaluates risks based on the OECD Guidance.

In fiscal 2024, as a result of about 400 surveys carried out at major business units and production subsidiaries, 280 smelters and refiners were identified and the RMAP conformance rate was about 80%*6.

For smelters and refiners that are not yet conformant with RMAP and those with high risk levels, we urge their participation in RMAP through the supply chain. If any smelters or refiners have been found to be dealing with militant forces or complicit in serious human rights abuses, this information is shared with suppliers, with whom we discuss measures such as switching to RMAP-conformant smelters or refiners.

RMAP Conformance Rates for Designated Smelters and Refiners

| FY2022 | FY2023 | FY2024 | |

|---|---|---|---|

| RMAP conformance rate | 63% | 79% | 80% |

- Organisation for Economic Co-operation and Development.

- RMI: Responsible Minerals Initiative.

- CMRT (Conflict Minerals Reporting Template) is a free, standardized reporting template developed by the RMI.

- EMRT (Extended Minerals Reporting Template) is a free, standardized reporting template developed by the RMI. It covers the cobalt and mica supply chains.

- RMAP (Responsible Minerals Assurance Process) is an RMI program for validating conformance of RMI-listed smelters or refiners.

- As of March 2025.

Education and Awareness Raising on Responsible Minerals Procurement

To deepen employees’ understanding of responsible minerals procurement, as a rule we hold monthly meetings with those in charge of surveys at major business units and production subsidiaries, where participants share information on the latest international developments and discuss practical survey issues and how to improve the survey system.

Procurement personnel and new employees take part in periodic supply chain CSR training, which covers responsible minerals procurement. Another way we further employees’ understanding on responsible minerals procurement is by uploading new and relevant material to the management skills improvement training page on the Sharp intranet.

Furthermore, for the supply chain, we are also active participants in JEITA’s Responsible Minerals Sourcing Inquiry Briefings from the planning phase onward, such as by creating documents and running the sessions, as part of our efforts to spread understanding of responsible minerals procurement in the industry supply chain and boosting the capabilities of downstream companies. We periodically send outreach letters to smelters or refiners that are not yet participants of the RMAP (created and operated by the RMI) urging them to undergo audits. These efforts are part of our contribution to effectively stamping out human rights abuses and other problems in the global procurement of minerals.

Due Diligence Efforts in Line with OECD Guidance

To carry out responsible minerals procurement, Sharp integrates into its management a five-step framework for risk-based due diligence recommended in the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas (OECD Guidance).

| OECD Five-Step Framework | What Sharp Is Doing |

|---|---|

| Step 1: Establish strong company management systems |

|

| Step 2: Identify and assess risk in the supply chain |

|

| Step 3: Design and implement a strategy to respond to identified risks |

|

| Step 4: Carry out independent third-party audit of supply chain due diligence at identified points in the supply chain |

|

| Step 5: Report on supply chain due diligence |

|