Safety and Security

Sharp’s Policy on Management of Chemical Substances

Sharp’s products are built from a plurality of parts and materials and contain wide-ranging chemical substances. Our production processes at factories also use chemical substances.

Chemical substances are useful for enhancing the performance and quality of products, whereas some of them may have negative effects on the natural environment and human health. Today, regulations to manage chemical substances are implemented in many countries. Some include prohibited or restricted use of specified chemical substances and labeling requirements, and others require the management of information on product content data, reporting of the amounts discharged into the atmosphere and water areas, management of the working environment, and occupational health management.

In accordance with our Basic Environmental Policy of “Creating an Environmentally Conscious Company with Sincerity and Creativity,” the Sharp Code of Conduct stipulates the management of chemical substances as follows, on the precondition of compliance with applicable environmental laws, regulations, and regional agreements.

- We will work to compile information related to hazardous substances that might damage the environment or human health, and will not, as a matter of principle, make use of these hazardous substances in our products and services.

- We will ensure proper use and control, and also reduce our consumption of chemical substances in our business activities, including research, development, and manufacturing, at levels meeting or exceeding those stipulated by laws and regulations.

To “properly manage chemicals in order to protect people’s health, the natural environment, and ecosystems” is another goal of Sharp. It is a long-term objective set in the SHARP Eco Vision 2050 long-term environmental vision in the safety and security field of action.

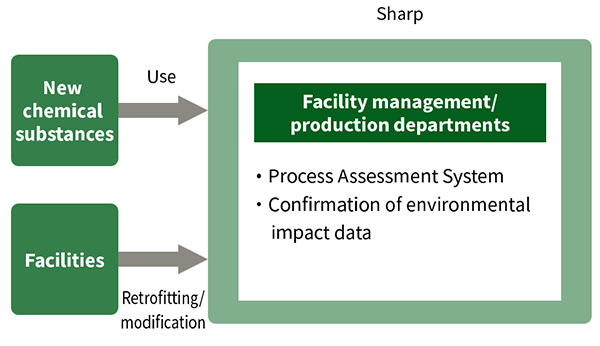

As an example of our efforts to manage chemical substances in products, we cooperate with our suppliers to manage information on chemicals contained in components and materials throughout the entire supply chain. For equipment and production at the factory-level, we have a process assessment system in place. This is a preliminary assessment of new chemical substances to be used or equipment retrofitted or modified for handling chemical substances and is performed to check their safety and environmental impact.

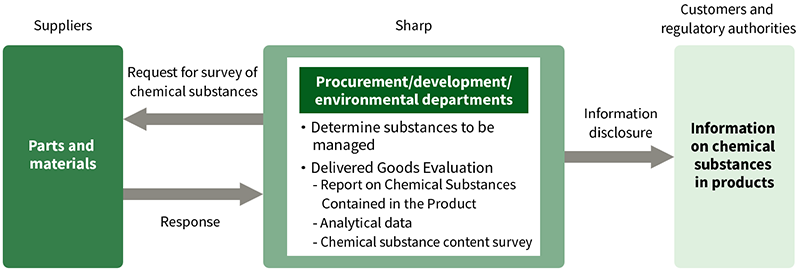

Chemical Substance Management System in the Product Supply Chain

Chemical Substance Management System in Manufacturing

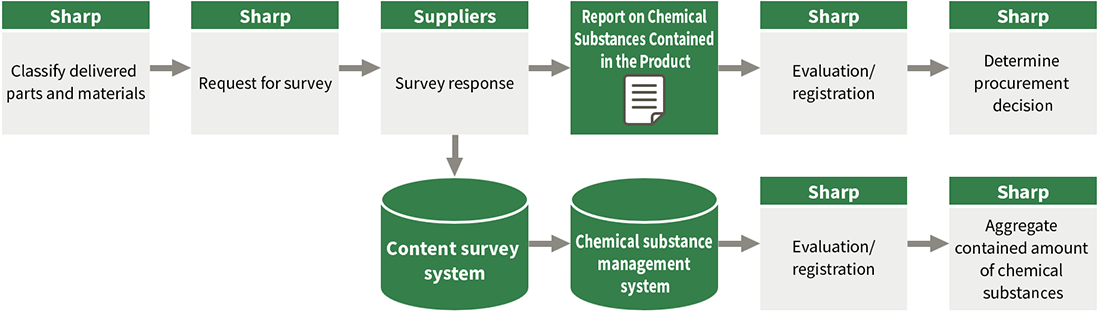

Managing Chemical Substances Contained in Products

Target Substances

In order to reduce environmental impacts of its products and to comply with chemical substance regulations in relevant countries, Sharp manages chemical substances contained in its products in accordance with its own management categories that take into account applicable laws and regulations in relevant countries, voluntary standards set by industry groups, and even potential future regulations.

Report on Chemical Substances Contained in the Product and Analysis Data

In order to ensure compliance with relevant countries’ regulations, such as the EU’s RoHS Directive*1, which prohibits the use of specific chemical substances in products, Sharp’s suppliers submit a Report on Chemical Substances Contained in the Product before delivering new components or materials for the first time. Based on the chemical substance management categories, this report checks the content status of banned substances (both banned substances and substances banned depending on the application) and candidate substances to be banned.

Suppliers must also submit analysis data on the 10 substances*2 regulated under the EU RoHS Directive for confirmation of compliance with the regulatory requirements. Sharp performs annual reviews of these Reports on Chemical Substances Contained in the Product in order to ensure compliance with legal regulations on the prohibition of specific chemical content, which have been increasing in recent years.

Chemical Substance Content Survey

In order to comply with legal regulations, including the EU REACH regulation*3, that oblige companies to communicate and disclose information on chemical substances contained in their products, Sharp conducts IT system-driven chemical substance content surveys. For information collection, Sharp utilizes chemSHERPA*4, an information sharing scheme compliant with the IEC 62474*5 international standard.

Chemical Substance Management Categories

| Category | Description | Remarks |

|---|---|---|

| Banned substances | Substances that cannot be used for any purpose |

|

| Substances banned depending on the application | Substances regarded as banned by Sharp depending on the application (excluded applications) | |

| Candidate substances to be banned | Substances that are candidates for being banned; substances to be substituted if contained in products |

|

| Managed substances | Substances for which it is necessary to ascertain whether the specified substance is present, the amount contained, and so on |

|

Process for Managing Chemical Substances Contained in Products

- An EU directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment.

- Lead, mercury, cadmium, hexavalent chromium, PBB, PBDE, DEHP, BBP, DBP, and DIBP

- A regulation covering the registration, evaluation, authorization, and restriction of chemical substances.

- An information sharing scheme developed under the leadership of the Japanese Ministry of Economy, Trade and Industry for the purpose of efficiently communicating information on chemical substances in products over the entire supply chain.

- An international standard on the procedures and details of information sharing in the supply chain for products and components in the electrical and electronics industry containing chemical substances.

Effective Management of Chemical Substances Used at Factories and Their Risk Management

Sharp strives to minimize the risk of environmental pollution and accidents associated with chemical substances and to properly meet chemical substance regulations. To this end, Sharp controls chemical substances used at, and released from, its production bases by implementing the process assessment system and the monitoring and risk management of chemical substances.

To minimize the environmental impact and ensure occupational safety, workers handling chemical substances go through regular education and training. They also receive regular health checks.

Process Assessment System

The process assessment system is Sharp’s in-house system for preliminarily assessing the hazards, safety measures, and other factors of chemical substances. This assessment applies when a new chemical substance is to be introduced or when the procedure for handling chemical substances needs to be changed, for example. The system ensures that chemical substances are properly managed at all stages from procurement to disposal and that safety measures are implemented for the equipment handling them. It is designed to review the appropriate disposal of waste chemical substances, the proper treatment of exhaust gas and wastewater, and safety procedures for workers handling chemical substances, and to evaluate and determine the conditions for the safe use of chemical substances.

Chemical substances are grouped into four categories according to their gravity of impact on safety/health, hazard/explosion, and environmental conservation: legally banned substances, sensitive substances, managed substances, and registered substances. An appropriate management level is assigned to each category.

Chemical Substance Management Categories under the Process Assessment System

| Category | Description |

|---|---|

| Legally banned substances | Chemical substances that are banned for production, etc. under laws and regulations. Substitutes for them need to be searched for. |

| Sensitive substances | Chemical substances that are not legally banned but are banned by Sharp for use due to their high levels of toxicity (acute toxicity/carcinogenicity) or hazards (explosiveness/flammability). Substitutes for them need to be searched for. |

| Managed substances | Chemical substances that have toxicity (corrosiveness/irritancy), hazards (combustibility/spontaneous combustibility) ,or other concerns but may be used under adequate control. |

| Registered substances | Chemical substances that have limited toxicity or hazards and thus may be used under specified control. |

Monitoring and Risk Management of Chemical Substances

Sharp has established voluntary standards that are stricter than either the regulatory requirements or the levels agreed upon with local communities for chemical substances used at its production bases. These standards ensure the comprehensive monitoring and management of the target chemical substances released and transferred, as well as the concentrations and emissions of air and water pollutants.

Release and Transfer of PRTR-Listed Substances

Sharp monitors and reports the release and transfer of chemical substances covered by the Japanese PRTR*1 Act. Of these PRTR chemicals, 24 were handled in Japan and five overseas*2 in quantities of 500 kg or more by one or more plants during fiscal 2024.

- PRTR: Pollutant Release and Transfer Register. A system that mandates the collection and dissemination of information, such as the amount of harmful chemicals discharged and transferred.

- Sharp defines target substances based on laws in Japan.

PRTR Data for Japan (Fiscal 2024)

(kg)

| PRTR No. |

Chemical | Amount Handled | Amount Discharged | Amount Transferred | Amount Consumed | Amount Removed | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Into Atmosphere | Into Public Water Areas | Into Soil | Into Sewerage | Into Waste, etc. | Contained in Products | Recycled | ||||

| 1 | Zinc compounds(water-soluble) | 1,683 | 0 | 0 | 0 | 0 | 1,436 | 0 | 247 | 0 |

| 20 | 2-Aminoethanol | 979,764 | 695 | 0 | 0 | 0 | 30,159 | 0 | 845,775 | 103,135 |

| 44 | Indium and its compounds | 22,272 | 0 | 0 | 0 | 0 | 3,873 | 2,324 | 16,075 | 0 |

| 80 | Xylene | 3,840 | 19 | 0 | 0 | 0 | 0 | 0 | 0 | 3,821 |

| 83 | Cumene | 560 | 0 | 0 | 0 | 0 | 10 | 0 | 550 | 0 |

| 135 | 2-methoxyethyl acetate | 104,000 | 625 | 0 | 0 | 0 | 0 | 0 | 80,790 | 22,585 |

| 232 | N, N-dimethylformamide | 30,774 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 30,774 |

| 272 | Copper salts (water-soluble, except complex salts) | 57,413 | 0 | 0 | 0 | 0 | 44,074 | 11,024 | 1,450 | 865 |

| 343 | Pyrocatechol (also called catechol) | 2,585 | 0 | 0 | 0 | 0 | 2,585 | 0 | 0 | 0 |

| 374 | Hydrogen fluoride and its water-soluble salts | 619,677 | 1,932 | 0 | 0 | 378 | 356,340 | 0 | 35,101 | 225,926 |

| 401 | 1,2,4-benzenetricarboxylic 1,2-anhydride | 1,636 | 0 | 0 | 0 | 0 | 495 | 856 | 285 | 0 |

| 405 | Boron compounds | 4,536 | 21 | 0 | 0 | 0 | 4,091 | 73 | 351 | 0 |

| 412 | Manganese and its compounds | 20,595 | 0 | 0 | 0 | 0 | 442 | 20,153 | 0 | 0 |

| 438 | Methylnaphthalene | 9,868 | 45 | 0 | 0 | 0 | 0 | 9,823 | 0 | 0 |

| 453 | Molybdenum and its compounds | 12,190 | 0 | 0 | 0 | 0 | 3,274 | 366 | 8,550 | 0 |

| 594 | Ethylene glycol monobutyl ether | 16,910 | 1,381 | 0 | 0 | 0 | 4,847 | 0 | 86 | 10,596 |

| 627 | Diethylene glycol monobutyl ether | 1,329,410 | 1,983 | 0 | 0 | 0 | 1,909 | 0 | 759,495 | 566,023 |

| 665 | Cerium and its compounds | 977 | 0 | 0 | 0 | 0 | 977 | 0 | 0 | 0 |

| 674 | Tetrahydrofuran | 6,075 | 469 | 0 | 0 | 0 | 1,506 | 0 | 0 | 4,100 |

| 677 | Tetramethylammonium hydroxide | 1,943,430 | 202 | 0 | 0 | 0 | 326,547 | 0 | 1,370,031 | 246,650 |

| 691 | Trimethylbenzene | 23,183 | 37 | 0 | 0 | 0 | 269 | 0 | 15,554 | 7,323 |

| 746 | N-Methyl-2-pyrrolidone | 124,198 | 2,595 | 0 | 0 | 0 | 8,836 | 0 | 85,193 | 27,574 |

| 751 | 2-(2-Methoxyethoxy)ethanol | 4,498,117 | 923 | 0 | 0 | 0 | 6,382 | 0 | 2,882,296 | 1,608,516 |

| 752 | 1-Methoxy-2-(2-methoxyethoxy)ethane | 14,901 | 0 | 0 | 0 | 0 | 11,533 | 1,828 | 1,540 | 0 |

| Total | 9,828,594 | 10,927 | 0 | 0 | 378 | 809,585 | 46,447 | 6,103,369 | 2,857,888 | |

Overseas PRTR Data (Fiscal 2024)

(kg)

| PRTR No. |

Chemical | Amount Handled | Amount Discharged | Amount Transferred | Amount Consumed | Amount Removed | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Into Atmosphere | Into Public Water Areas | Into Soil | Into Sewerage | Into Waste, etc. | Contained in Products | Recycled | ||||

| 82 | Silver and its water-soluble compounds | 1,057 | 0 | 0 | 0 | 0 | 155 | 902 | 0 | 0 |

| 300 | Toluene | 7,933 | 7,933 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 591 | Ethylcyclohexane | 585 | 410 | 0 | 0 | 0 | 175 | 0 | 0 | 0 |

| 392 | N-hexane | 50,314 | 50,314 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 448 | Methylenebis(4,1-phenylene) diisocyanate | 1,488,652 | 0 | 0 | 0 | 0 | 28,190 | 1,460,462 | 0 | 0 |

| Total | 1,548,541 | 58,657 | 0 | 0 | 0 | 28,520 | 1,461,364 | 0 | 0 | |

Managing Environmental Load into Air and Water Areas

| Fiscal 2024 Objectives | Fiscal 2024 Achievements | Self-Evaluation | Priority Objectives for Fiscal 2025 |

|---|---|---|---|

|

|

★★ |

|

- Self-evaluation: ★★★ Achieved more than targeted / ★★ Achieved as targeted / ★ Achieved to some extent

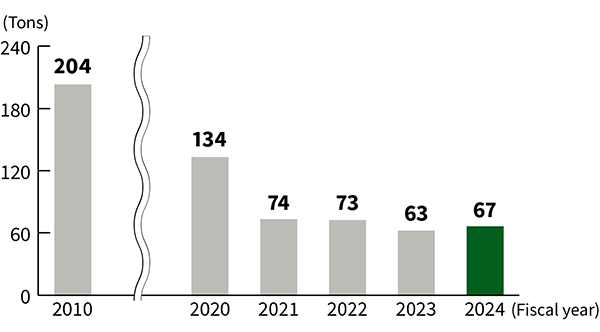

Reducing VOCs

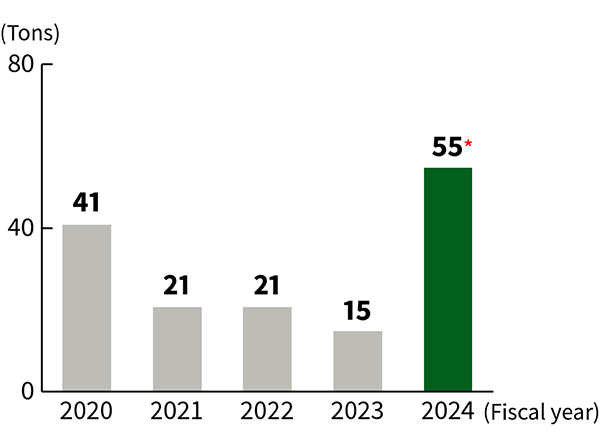

Sharp strives to reduce the volatile organic compounds (VOCs) it emits. It has set a target of keeping VOCs released into the atmosphere to no higher than fiscal 2010 levels (based on a voluntary action plan by the Japanese electrical and electronics industry). Fiscal 2024 VOC emissions were 67 tons, lower than the amount emitted in fiscal 2010 (204 tons), thus achieving the target.

Sharp is reducing VOCs with the installation of highly efficient abatement facilities in LCD production sites, a major source of VOC emissions.

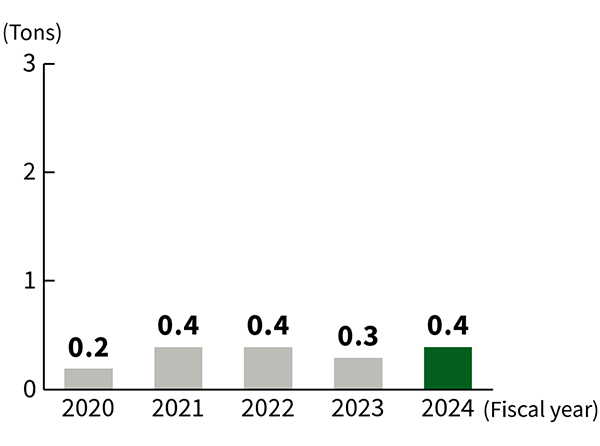

VOC Emissions into the Atmosphere

Managing Environmental Load into Air and Water Areas

Sharp properly manages pollutants that affect air and water quality by establishing voluntary standards that are stricter than those set forth in laws and regulations and stricter than those agreed upon with local communities. It also actively conducts risk communication with local communities.

Atmospheric Emissions in Japan

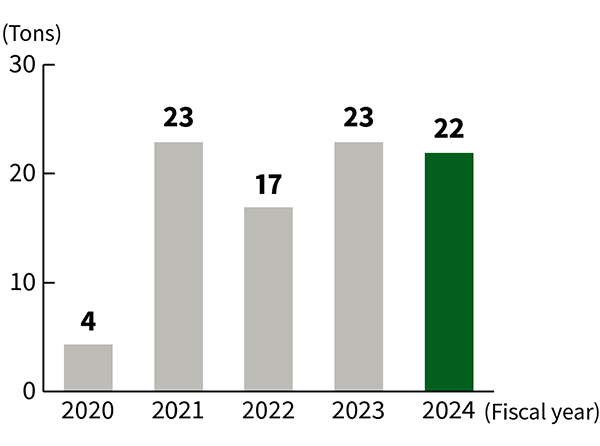

NOx Emissions

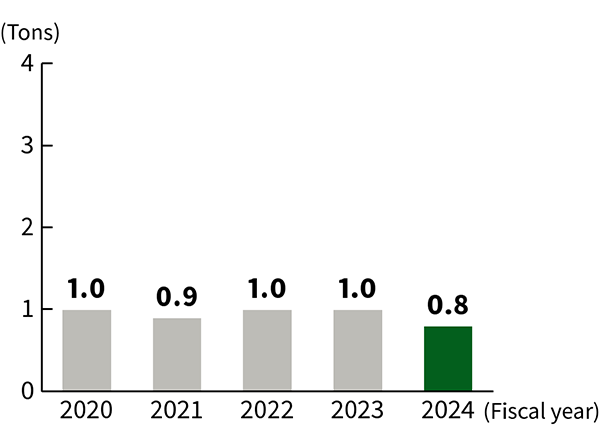

SOx Emissions

- Although emissions increased at some sites due to a change in the operation of NOx treatment equipment, Sharp still abided by pollution control agreements.

Emissions into Water Areas in Japan

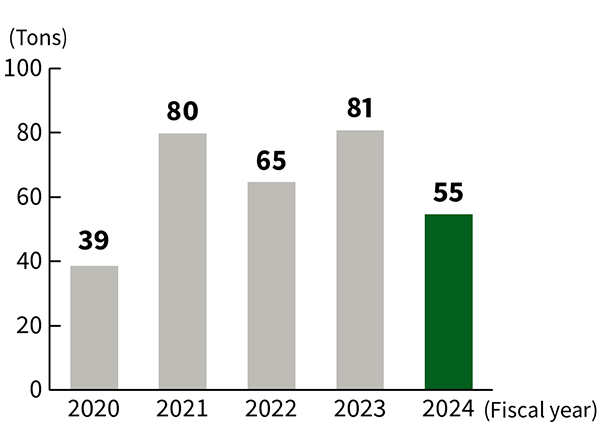

COD (Chemical Oxygen Demand)

Nitrogen Pollutant Load

Phosphorous Pollutant Load

Risk Management of Soil and Groundwater Pollution

Sharp has established and is appropriately applying in-house standards to minimize the risk of environmental pollution and accidents caused by chemical substances. It also strives to prevent such incidents from occurring by taking multi-layered leakage prevention measures at facilities that handle chemical substances. For plants where chlorine solvent contamination was found in the past, Sharp regularly notifies local government authorities and others of the cleanup progress.

Analyzing Plant Wastewater Samples

The Nara Plant in Yamatokoriyama, Nara Prefecture, conducts its own monthly voluntary checks on plant wastewater. It also works with the Yamatokoriyama city government to analyze wastewater four times a year, as part of its risk communication activities. Each party conducts its own analysis, before sharing their results and exchanging insights. This process gives Sharp the opportunity to build strong relationships with everyone involved.